The Greenhub working group is researching highly automated, vertical systems for food production. Their use is to be integrated into sustainable urban development in the future. The research is based on the technical and biological implementation of vertical microponic systems.

Background

Major German and European cities are particularly dependent on global food supplies. However, economic crises, pandemics, environmental pollution and the effects of climate change pose a risk to the stability of food chains. In addition, the Food and Agriculture Organization of the United Nations (FAO, 2017) predicts that agriculture will have to produce 70% more food by 2050 to meet the needs of the world's population, which is expected to grow to 9.8 billion people.

Urban vertical farming is a promising approach to counteract the effects of climate change and resource scarcity as well as to contribute to food security in Germany and Europe in the long term. The weather-independent, indoor plant cultivation is characterised by a demand-based water and nutrient supply for food production, thereby demonstrating a considerable potential for saving these resources.

Vertical farming refers to cultivation methods in which fresh vegetables, herbs and fruits are grown in controlled systems on several levels in a rack-like arrangement. This type of cultivation is suitable for small areas with high building density, as it requires less land for cultivation.

Indoor agriculture refers to crop production using artificial lighting, e.g. LED lamps instead of sunlight, offering the possibility to control environmental conditions. This type of controlled agriculture can be realized in closed rooms like warehouses, containers, factories and other converted indoor spaces designed to grow crops.

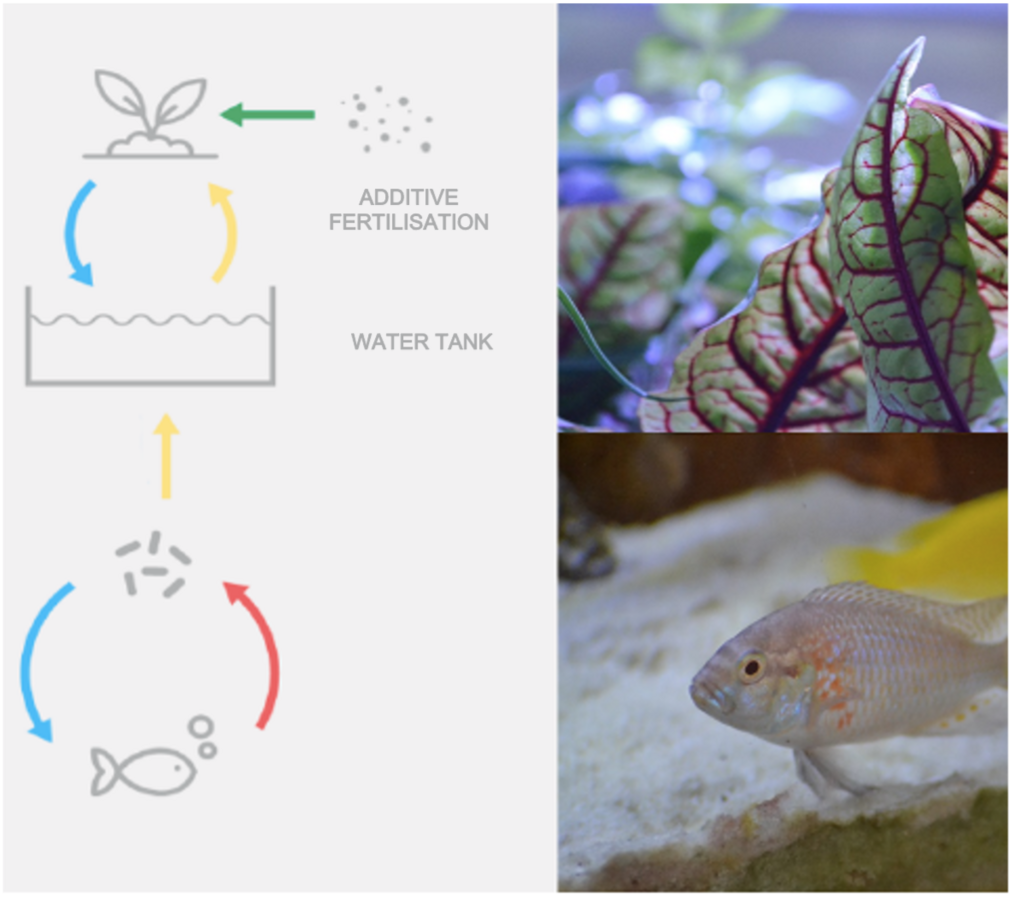

This cultivation method combines the cultivation of plants and fishs. In an aquaponic system, a synergy is created between fish, micro-organisms and plants. The nutrient-rich water of the fish is used as a fertiliser base for the plants. The plants absorb the nutrients and thereby purify the water. With aquaponics, the water demand can be reduced by up to 90% (compared to conventional agriculture). Due to the reduced use of fertilisers, aquaponics are one of the most resource-efficient cultivation methods.

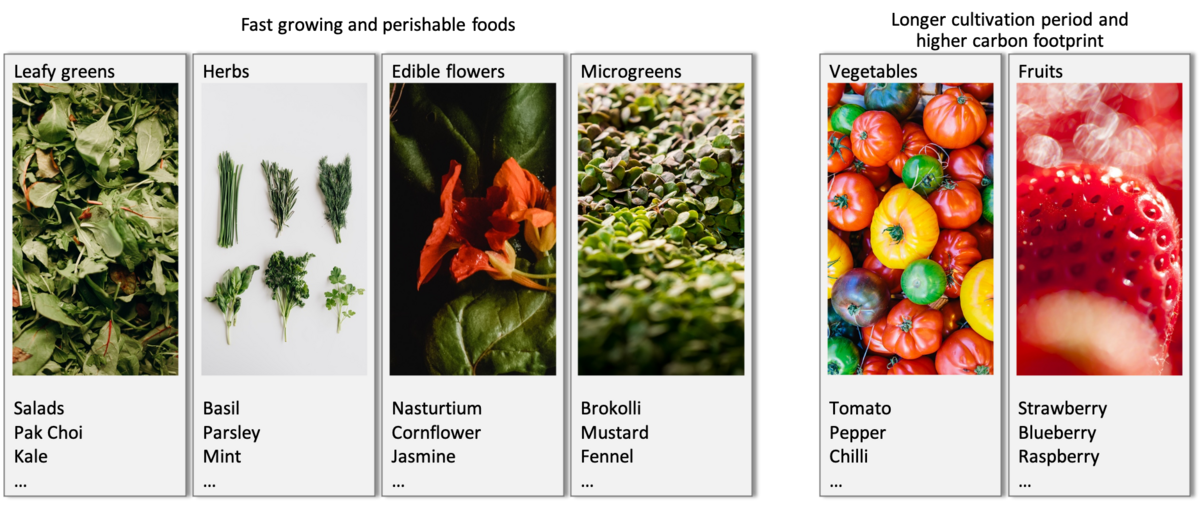

Due to the increased energy demand compared to outdoor cultivation and with regard to economic efficiency, the focus is currently on fast-growing and perishable foods. A holistic energy concept for the building in which the systems are operating / or incooparated (waste heat recovery, renewable energies, etc.) means that fruiting vegetables and fresh fruits can also be grown in an environmentally friendly way.

In order to achieve a measurable impact in local food supply in urban environments with vertical indoor farming, the industry is relying on new technologies. For economic reasons, the technology-driven farming method aims to automate and continuously replicate the growth of living plants. The inherent complexity of this development due to dependencies on many complex parameters means that the potential to increase quality and yield of this cultivation method has still very high. In addition, the optimization is lengthy and cost-intensive due to an elaborate system design and the repetitive growth cycles of the plants.

Research Work

Since the beginning of the research work within the framework of the BMBF ideas competition "New Products for the Bioeconomy", research has been conducted on this complexity of the technical and biological implementation of vertical microponic systems. The focus is on technology development for small-scale systems in order to increase the quality and yield potential of plant and fish cultivation in such recirculating systems. The objective of the research work is to develop controllable and adjustable multi-loop systems that can be continuously optimized with regard to resource efficiency and environmental compatibility.

The knowledge gained so far was combined in its technical and biological processes in a technology demonstrator. The developed technology demonstrator was already presented at the Hannover Fair at the joint stand of Projektträger Jülich (PTJ).

The data obtained from the determination of parameters for healthy plant and fish growth will be used to research automated, vertical systems for urban food production. The use of these systems will be integrated into sustainable urban development in the future.

Greenhub - Innovation

The micro-aquaponics systems designed within the working group are characterized by highly automated multi-loop systems and the control of all functions by means of a self-developed application. The multi-loop approach enables hydroponic and aquaponic experiments to be carried out. These systems enable R&D players from industry and research to explore the complexity of vertical indoor agriculture and aquaponics in a space-saving cabinet system. By integrating a variety of sensors into the sophisticated system, rapid scientific advances can be made. Thus, with the help of the Greenhub technology, hygienically stable cultivation concepts for vertical farming and recirculating systems can be developed and established in a time-saving manner, which can then be applied for upscaling in large-scale facilities.

The Greenhub - a fully controllable microponic system consisting of two circuits. Four partial innovations, which in their entirety represent a novelty.

Through a multi-loop system, system-inherent biochemical processes can be controlled to ensure optimal nutrient supply to plants and fish. Pure hydroponic systems generally apply pH settings between 4.5 and 6.0 for water-based plant cultures (Resh, 2013), while aquaculture typically applies pH settings between 7.0 and 8.0 (Timmons et al., 2002) to meet the requirements of fish and the microorganisms found present (which perform important conversions of potentially toxic fish waste metabolites into less toxic forms). Due to the different requirements of the fish and plant habitat in terms of pH as well as EC, the loops are split.

This regulates the automatic nutrient management for optimal plant growth. With this autodosing unit for nutrient control in the plant units, the water circulation is separated from the fish unit to realize the multi-loop system. In addition, the nutrient solution is adjusted to the cultivated plants and the setted light conditions in order to achieve an optimal nutrient supply for the plants. The important parameters here are the pH value and the electrical conductivity (EC value). Both values are measured continuously and adjusted precisely by milliliters via dosing pumps.

The adjustment of light values and recipes for optimal plant growth is done using in-house developed, controllable full-spectral LED lights. With 8 colour channels per panel, light values in the PAR range can be set (photosynthetically active radiation, PPFD and DLI also adjustable). The range of the light spectrum of our LED matches 425nm to 700nm + 730nm.

This range is mainly used by plants for photosynthesis. Depending on the plant species, the proportional needs for short-wave, high-energy blue spectrum light for the growth phase to long-wave red spectrum light for the flowering phase are addressed individually. The combination of the different wavelength ranges helps the plants to increase their photosynthesis rate and to grow better. Furthermore, with the help of the light composition, positive ingredients can be actively enriched in the plants.

The core of the Greenhub unit is the input and output optimization through the self-developed web application. The objective is to exploit the advantages of controlled indoor farming of 95 % water and 70 % fertilizer savings, while still focusing on quality improvement. All important sensor data can be read out via the dashboard and the crucial parameters for plant growth can be set.

So far, more than 40 different plant species such as salads, herbs, tomatoes, strawberries and chillies have been successfully grown in the functional models.

Since June 2021, the working group has been working with pilot customers as part of the EXIST start-up grant to turn the Greenhub innovation into a market-ready technology. Within the funding phase, the Anchor Group Aquaculture Research of the Alfred Wegener Institute Helmholtz Centre for Polar and Marine Research is testing the first growth cycles of fish and plants in the field of their aquaponics research with two prototypes.

Together with Basislager Leipzig, the largest coworking space for tech start-ups, entrepreneurs and self-employed people in central Germany, the application of automated systems for integration into sustainable urban development is being piloted.

TEMIFUGA

Since April 2020, the working group has been contributing the findings from the BMBF funding to a cooperation project with Leipzig-based madebymade GmbH. In the "InnoTeam" funding programme of the Sächsische Aufbaubank (SAB), the cooperation partners are jointly researching sustainable value chains in food production.

The objective of the basic research is described as "Development of an innovative technology demonstrator for research into micro-cycle systems for food supply in conjunction with sustainable feed design based on biogenic residue-utilising insects using the example of the shrimp", short name: "TEMIFUGA".

There are major sustainability deficits in many value chains, especially in non-domestic food production. Since shrimp is one of the most demanded fishery and aquaculture products in Germany, as well as having massive negative environmental impacts during farming, it was chosen as a demonstration object. Alternatives are needed in the feed production of quality products such as shrimp in order to react sustainably to the problems of climate change with practical action. In addition to shrimp, the project was expanded to include crayfish trials, as these are very innovative and have high market potential. Local crayfish are ideal from the point of view of regionality, and the water for keeping them does not have to be heated, so they are more resource-efficient.

The project goal in the projected funding period is to develop small, decentralized, highly automated micro-shrimp farms as a technology demonstrator. These micro-shrimp farms are to be developed in the form of a prototype shrimp cabinet, combined with aquaponics. The intention here is to create sustainable value chains in food production. Through the efficient use of biogenic residues, high-quality regional food can be produced. The planned approach of the "Inno-Team" consists of a combination of automation technology, feed design, light and nutrient recipes. The unique combination of three innovative approaches, which is unprecedented in Saxony's business and research culture, is in line with Saxony's objective of boosting innovation.

01.04.2020 till 31.03.2022